How Do You Know When Plastic Is Bacolite

Is it Bakelite?

How to Determine if it's Old, Repro, Faux or a Look-alike

In 1984, a so-called "Philadelphia" Bakelite bracelet–a hinged mode with multicolored wedges on top–sold for $250. The aforementioned bracelets now bring over $4,000. Relatively common Bakelite bangles and pins which brought only $ten-$50 in the mid-1990s, are now priced at $l-$300.

Every bit prices have risen, so has the tendency for sellers, either through lack of knowledge or deliberate intent, to call whatsoever piece of plastic, "Bakelite." Reproductions are now common and there has been a steady increase in reworked and "married" pieces.

This commodity will explain how originals were made, the simple tests anyone can utilize to separate genuine Bakelite from expect-alike, and the common warning signs of new, fake and reproduction pieces.

What is Bakelite?

Bakelite is a trade proper noun taken from its inventor, Leo Baekeland, who invented Bakelite in 1907. Bakelite is made from carbolic acid (phenol) and formaldehyde and is referred to every bit a phenolic resin. Bakelite was the beginning thermosetting plastic. That means once a Bakelite product is formed, it will not change shape or melt under heat. Plastics formed from other formulas tin can exist reshaped subsequently reheating or volition burst into flame if reheated.

Bakelite was first used as insulators against heat and electricity. As means were found to manufacture Bakelite in brilliant colors, it began to exist used for all sorts of decorative objects, especially jewelry.

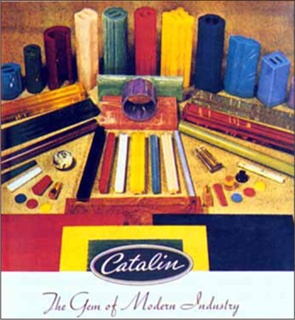

Although Bakelite was the trade name of the first thermosetting phenolic resin, it was not the but one. Other of import trade or make names include Catalin, Marblette, Prystal, Phenolia and a number of others. Since brand names rarely announced on the products, collectors by and large apply "Bakelite" to refer to all of the thermosetting phenolic resins, not simply to the Bakelite make products and that's how we'll utilise the term. Throughout this article, "Bakelite" volition refer to all phenolic resin pieces regardless of their original make proper noun.

How Bakelite was Made

One of the keys to identifying original Bakelite is to understand how it was manufactured. Modernistic hard plastics which are often confused with Bakelite, were generally produced by injecting or pouring a liquid resin into a mold which produced the final product. In other words, to go a domestic dog pivot, you'd pour plastic into a dog-shaped mold. The mold would create all the details of the finished product such as fur, eyes, neckband, etc. When the mold was opened, the final piece was essentially ready for sale.

Bakelite was very rarely molded into individual pieces of finished jewelry. The keen majority of Bakelite jewelry was made by mitt from stock shapes of raw material. Bakelite'due south unique properties lent itself to extrusion casting. If you wanted to brand bracelets, for example, you lot'd extrude a long tube with the crude shape (Fig. four) preformed. Workers would so piece off various widths from the tube, decorate, and shine them past mitt. The buckles in Fig. 5 were sliced from tubes extruded with the buckle shapes preformed. Considering decorating was done by paw, special designs and small-scale custom orders could easily be made without the overhead of expensive molds required past hard plastics. Anyone could buy the raw Bakelite material and minor studios and amateurs could afford to experiment with their ain jewelry designs.

Tests for Genuine Bakelite

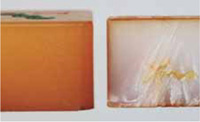

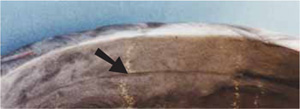

Dissimilar other plastics, authentic Bakelite oxidizes over the years developing a patina which changes the surface color. Exposure to sunlight, body fluids, cosmetics and other factors contribute to patinas and color changes associated with normal age and wear. An example of typical colour change is shown in Fig. half-dozen

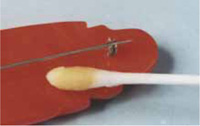

Normal oxidation provides a valuable clue whether a suspected piece is true Bakelite (phenolic resin) or a wait-alike material. All true Bakelite, regardless of surface color (Figs. 7-8), will leave an ivory or pale yellow smear on a cotton swab wetted with one of several common products: the cleaning fluids "409" and "Scrubbing Bubbles" and "Simichrome Polish". Expect-alike materials such as modern hard plastics, will not leave any color on the swab or volition leave a smear the same the color as the plastic (blueish plastic will leave a blue smear, etc.).

All the testing products cause eye and skin irritation and should be used advisedly; prophylactic gloves are recommended. Use a tiny amount of material; information technology doesn't take much. Utilise to a pocket-size, hidden area such as the back side of a pin or within of a bracelet. Scrubbing Bubbles tin can dull the original finish; Simichrome volition get out the tested expanse with a higher smooth; 409 leave the surface most unchanged and is the all-time choice.

Nearly non-Bakelite products are non afflicted by the products, just yous should always be careful and carefully wash and wipe dry all tested areas to forestall any possible long-term changes.

The swab examination is effective on virtually all Bakelite. The most common exceptions are pieces of genuine Bakelite that take recently been completely polished or cleaned and the original patina has been removed. Certain colors, specially black and some reds, can too occasionally give confusing results.

Another easy, simple test is to place a suspected slice under hot h2o from your household faucet. Concur the slice so an edge is in the centre of the menses. After 20-30 seconds, quickly hold the slice up to your olfactory organ. The vast bulk of genuine Bakelite gives off a potent phenol odor similar to paint remover or varnish. Modern plastics and other expect-alike materials practise non produce any smell when held under hot water produced by the boilerplate household hot h2o heater.

Other Considerations

Once you determine a piece is made from genuine Bakelite, it doesn't mean y'all have proved the piece is necessarily old. There is a surprising corporeality of original unfinished Bakelite stock that has survived. This sometime but never-used stock, tin be carved today (Fig. 17) and offered as vintage Bakelite. Genuine vintage jewelry that is plain and low value, is frequently carved into more desirable and college priced designs. One-time stock and carved pieces will both laissez passer the swab and hot water tests because the pieces are 18-carat Bakelite.

One way to confirm historic period is to carefully examine the findings, or hardware, such as pins, hinges, etc. Findings on genuine vintage Bakelite jewelry are generally attached with mechanical fasteners such equally tiny screws, pins and nails. Findings in modern plastic are typically cast into the jewelry as it is being poured or glued on afterward. Original metallic findings nearly always shows some tarnish or even rust. Beware of shiny hardware with no sign of normal age or wear.

Since genuine Bakelite produces a patina, outer surfaces on truly vintage pieces should normally exist darker than protected inner surfaces. Insides of bracelets, for example, should be lighter in colour than the exposed outer surfaces. Backs of pins and earrings should also be lighter than exposed outer surfaces.

Virtually all authentic Bakelite jewelry was mitt machined or carved and should show some tool marks. Vintage tool marks are, all the same, at the very least, tumbled and rounded off, never jagged or sharp. Grinding marks with a frosted, chalky appearance are typical signs of contempo etching.

Tool marks should as well be logical. An original carver, working by the hr or slice-rate, would spend more fourth dimension finishing exposed surfaces rather than finishing subconscious surfaces that were non exposed. Tool marks in subconscious areas are more than obvious than marks on exposed surfaces. Surfaces of reworked or newly carved pieces are sometimes completely polished on all sides, regardless if the surface is exposed or hidden.

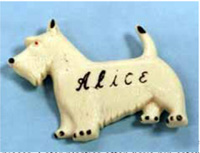

Warnings signs of typical reproductions, copies and wait-alike Bakelite are shown at the top of the next page. 1 of the more obvious signs that a piece could not possibly be a piece of Bakelite is a mold seam. Authentic Bakelite, fabricated slice by piece with mitt finishing, never has a mold seam. Modernistic hard plastics produced in a mold, virtually e'er accept a mold seam (Fig. 19)

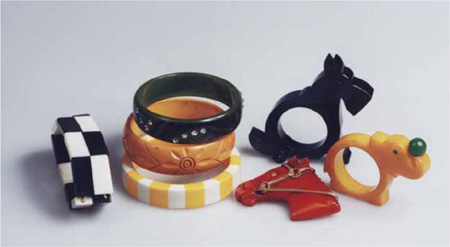

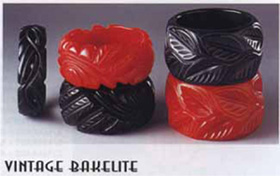

Fig. one Today's marketplace is filled with expect-akin Bakelite. These disruptive pieces range from genuinely quondam celluloid to plastic products from the 1950-60s too every bit deliberate fakes and reproductions. Only four of the seven pieces shown above are genuine Bakelite.

Fig. 2 When mixed with wood or paper fibers, Bakelite is dull brown or black. Information technology volition not conduct heat or electricity. Typical knob on pot lid shown here.

Fig. 3 Brightly colored Bakelite gradually began to be used for for ornamental trim. Shown here equally knob and handle on Fine art Deco chrome creamer.

Fig. 4 Trade advertisement for Catalin showing array of typical stock shapes. Bangle/bracelet cylinder shown superlative row, tertiary from left. Several buckle and button cylinders in the back row. Catalin was a phenolic resin brand competing with Bakelite.

Fig. 5 Typical pieces sliced straight from stock cylinders and blocks every bit shown in Catalin advertisement. Paw finished into buckles and Mah Jong tile.

Fig. 6 Genuine Bakelite develops a patina over time and changes the color of the surface. Image above left shows outside surface colour of 1930s block of Bakelite. Right, piece sliced from cake on left showing original colour concealed below original surface.

Fig. 7 Dark dark-green Bakelite. Test swab shows ivory/stake yellow.

Fig. 8 Dark red Bakelite. Test swab shows ivory/pale yellow.

Fig. nine The iii virtually widely used materials to exam Bakelite. Left to right: 409 household cleaner, Scrubbing Bubbles bathroom cleaner and Simichrome Shine.

Fig. 10 When testing with hot water, heat merely the edge of an article. Use the thinnest edge bachelor for all-time results. Avoid wetting string, woods or metal that may be plant with Bakelite.

Features of Typical Vintage Bakelite Jewelry

Fig. xi Typical old pivot grab screwed into Bakelite.

Fig. 12 Old pivot catch driven into Bakelite.

Fig. 13 Swivel fastened with tiny nails. Note tarnishing in hinge, common in vintage hardware.

Fig. fourteen Exposed surfaces of vintage Bakelite are almost always darker than protected surfaces. Compare the outside surface of this genuine bangle (white pointer) to the inner surface which is lighter in color (blackness arrow).

Fig. 15 Two typical vintage Bakelite bangles with simple hand carving.

Fig. sixteen Tool marks on the back side of a typical vintage pin. Tool marks are by and large more obvious on the back side of vintage pieces than the exposed decorative surfaces.

Fig. 17 Offer for newly carved Bakelite bracelets from onetime stock. Red and black, widths 7/8″ to 1½″, priced $60 to $110. Original prices would be 3-4 times those prices. No oxidation or patina; within surfaces are the same color equally outer surfaces.

Warning Signs of Look-alike, Copies and Reproductions

Glued hardware is a also a sign of modern pieces, or at the very least, a repair. New pins are ordinarily glued to inexpensive Bakelite clothing buttons to make a piece of "jewelry." Remember, even if a piece passes the cotton swab test, it doesn't mean the hardware is original.

No original Bakelite will warp or bend under heat or exposure to wet. Whatsoever warped or distorted slice (Fig. 24) is not Bakelite just some other cloth such every bit modern hard plastic or 19th century celluloid.

Brightly colored vintage Bakelite was used for many items other than jewelry. Some of those items include napkin rings, pencil sharpeners and handles on a vast assortment of kitchen flatware, gadgets and tools. The same tests described in this article for Bakelite jewelry as well apply to these other objects. When testing Bakelite, always use safe, nondestructive tests similar those described in this article. Always ask the seller'southward permission earlier making any tests.

Fig. 18 Plastic bangles with molded carvings, ca. 1960s. These fail the cotton swab test and have a mold seam. (Fig. 19)

Fig. 19 Mold seam on inside of bangles shown in Fig. xviii Vintage Bakelite never has a mold seam. Mold seams are common in ordinary plastics.

Fig. 20

Fig. 21

Fastener glued to Bakelite clothing button, Fig. 20, to make a piece of "jewelry." Glued fastener on back of typical 1960-70s brooch, Fig. 21.

Fig. 22

Fig. 23

Fig. 22-23 All findings on vintage Bakelite are separate, practical pieces. Subsequently plastics often have pin catches, hinges and other parts cast as one piece with the jewelry.

Fig. 24 No authentic Bakelite volition warp, bend or lose its original shape due to heat or moisture. Any warped or misshaped piece like the bangle higher up, cannot be authentic Bakelite.

Fig. 25 Ii 1960-70s multicolored laminated pieces like to vintage Bakelite. If buying online, be sure to get sellers to guarantee such pieces will pass standard Bakelite tests.

Fig. 26 This new scottie napkin ring on wheels is available for $iv each. The originals sell for $75-$100. This new scottie has a blackness body with crimson eyes. It fails both the cotton wool swab and hot water tests.

hickersonainal1980.blogspot.com

Source: https://www.realorrepro.com/article/Is-it-Bakelite

0 Response to "How Do You Know When Plastic Is Bacolite"

Post a Comment